Start

Last July, an idea began to take shape in our minds: "How can we help people rest better?" This was the origin of the RestBase project. By August, the idea had become clearer, and development officially began.

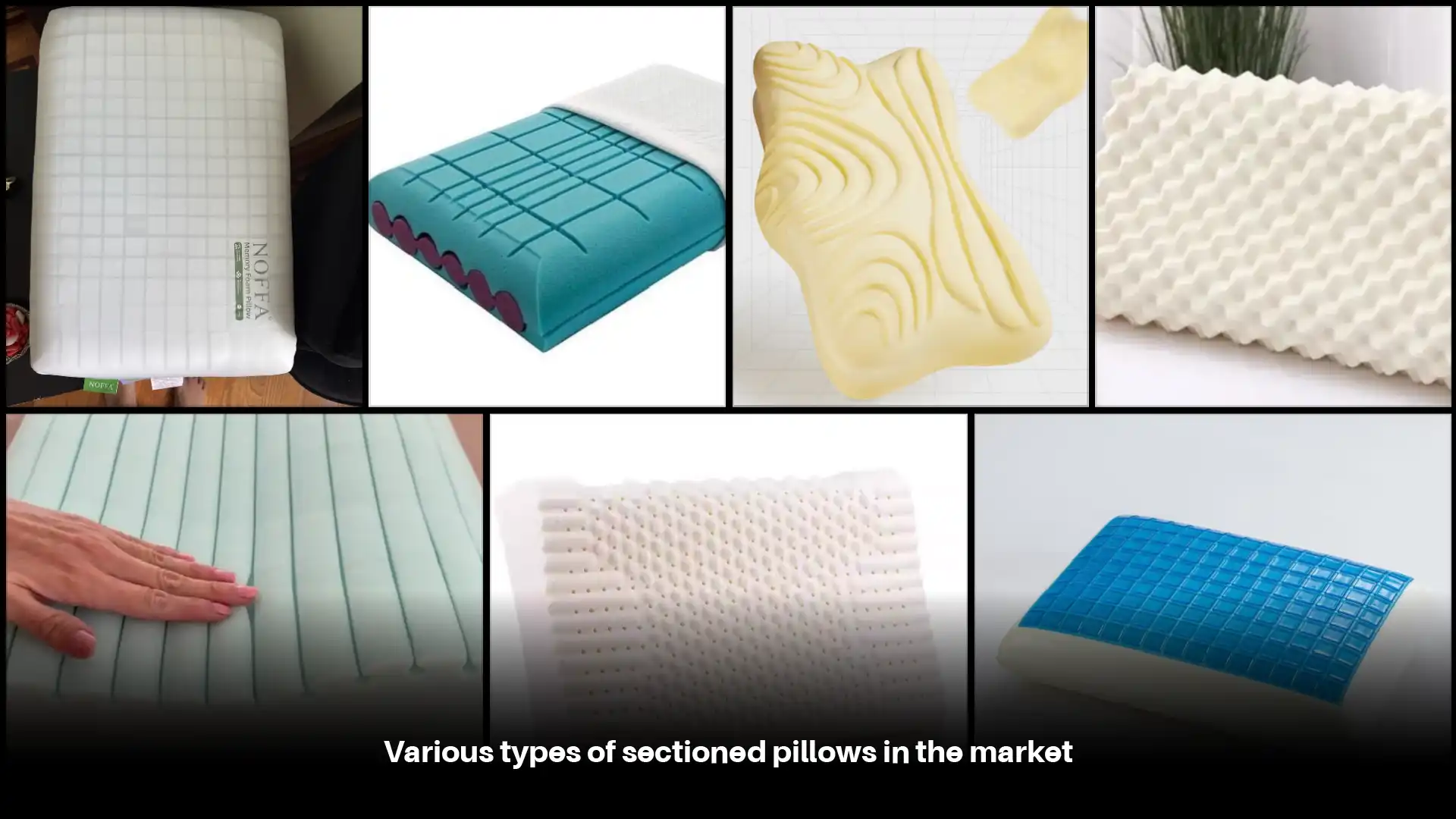

Our first step was to thoroughly research existing products in the market. Zoned designs are indeed the mainstream approach to improving pillow comfort, and a wide variety of zoned pillows are already available on the market...

But these designs seemed to be based on a "universal" assumption. We believe that true comfort comes from precision. So, a key question arose: How can we provide truly precise support for different users?

The key answer lies in real and diverse human data. We believe that true precision must be based on a broad sample. Therefore, we initiated a study that successfully involved over 1,200 volunteers from different backgrounds. Using 3D scanning, we created an incredibly detailed map of human head and neck contours.

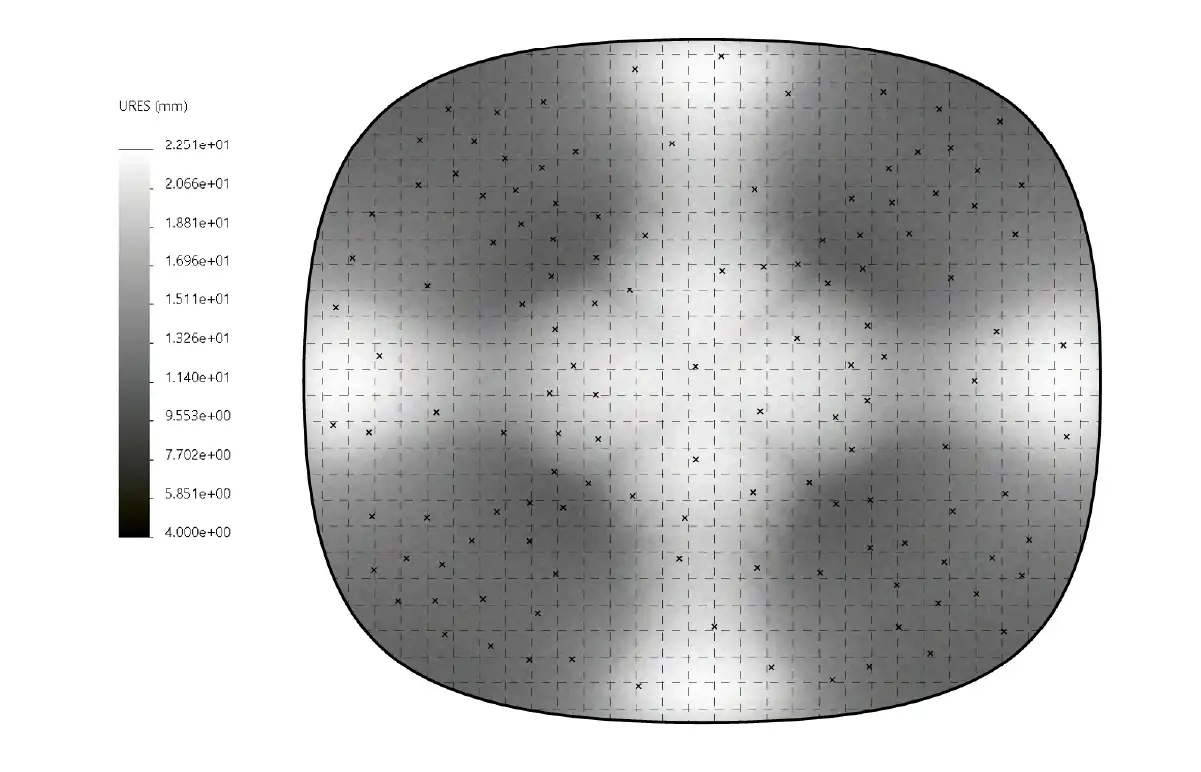

Based on this data, we conducted extensive modeling and pressure distribution simulations, ultimately creating a detailed "sleep pressure map." This map became the scientific blueprint for the precise support that defines Restbase.

The Key from Nature

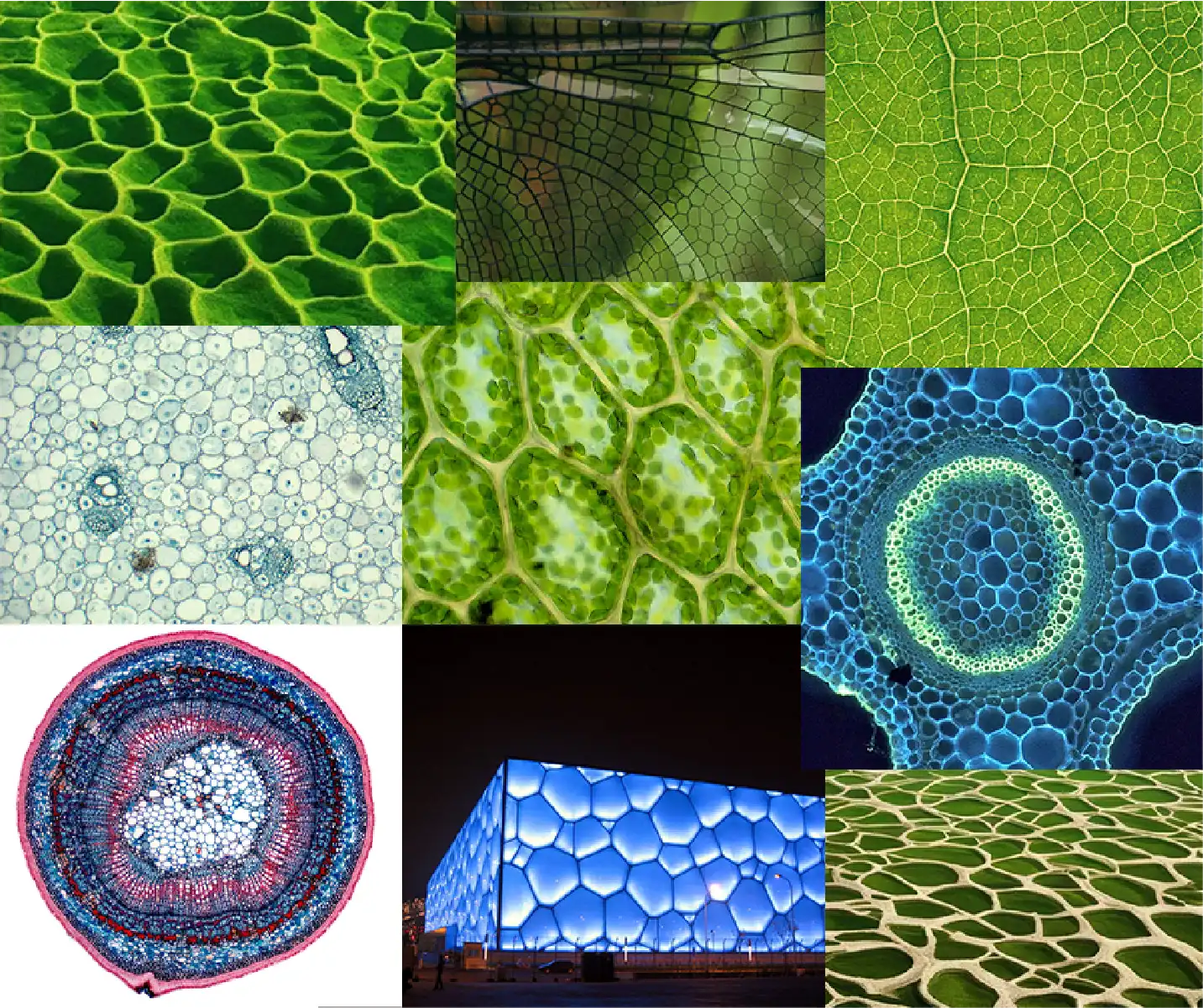

How could we transform over 1,200 sets of human data into precise zoning within a pillow? We hit a bottleneck. Then, during a casual conversation with researchers at the Biomechanics Lab of the Chinese Academy of Sciences, one of them suggested, "Look to nature. It has perfect blueprints for solving complex distribution problems."

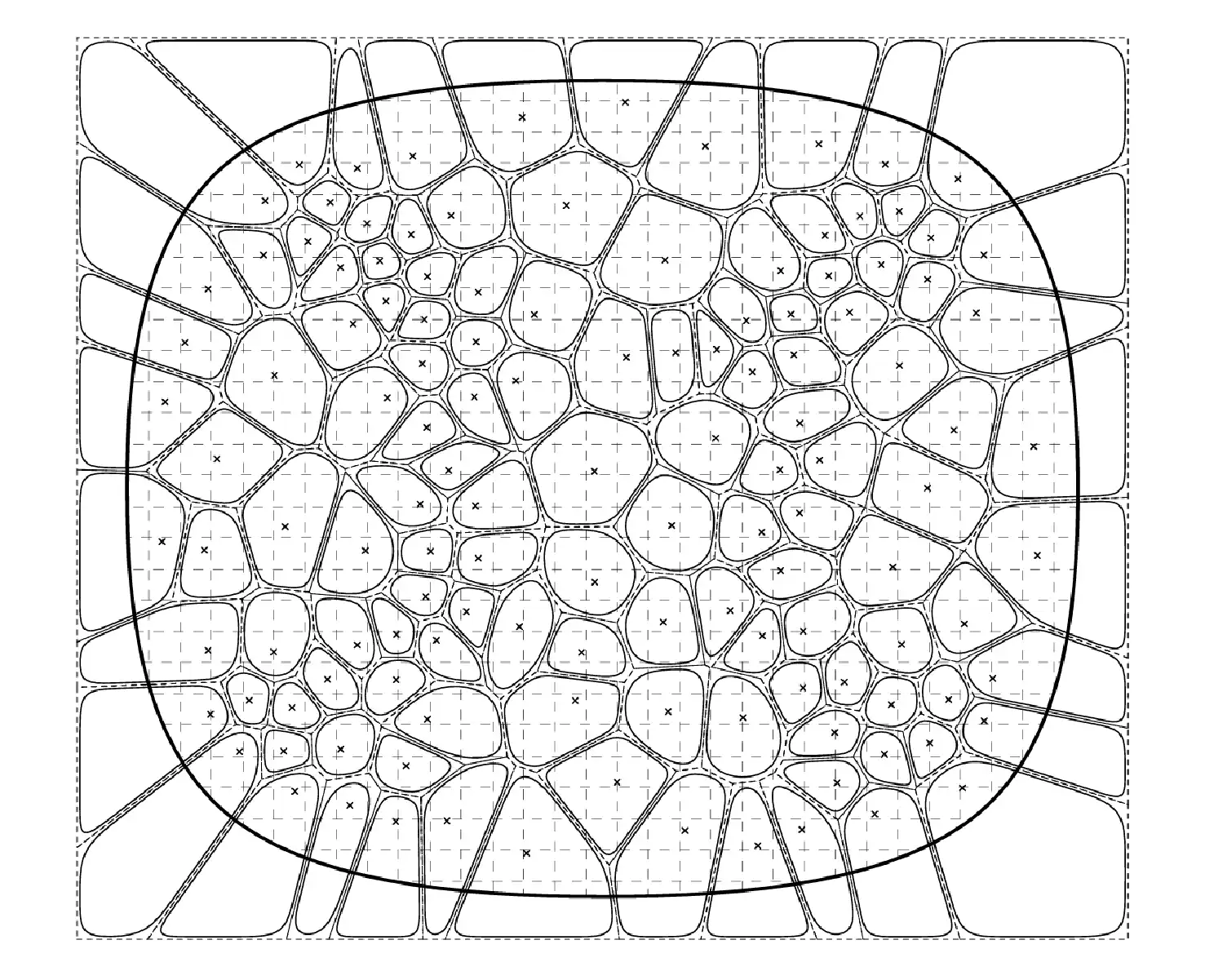

This insight immediately sparked our creativity, and we quickly zeroed in on a solution: the Voronoi diagram. This natural structure, commonly found in honeycombs and leaf veins, aligns perfectly with the mechanical principles of the pressure distribution model we had envisioned.

We discovered that this structure is nature’s perfect solution to the balance between resources, space, and stability. Similarly, our pillow also needed to strike the perfect balance between these three elements.

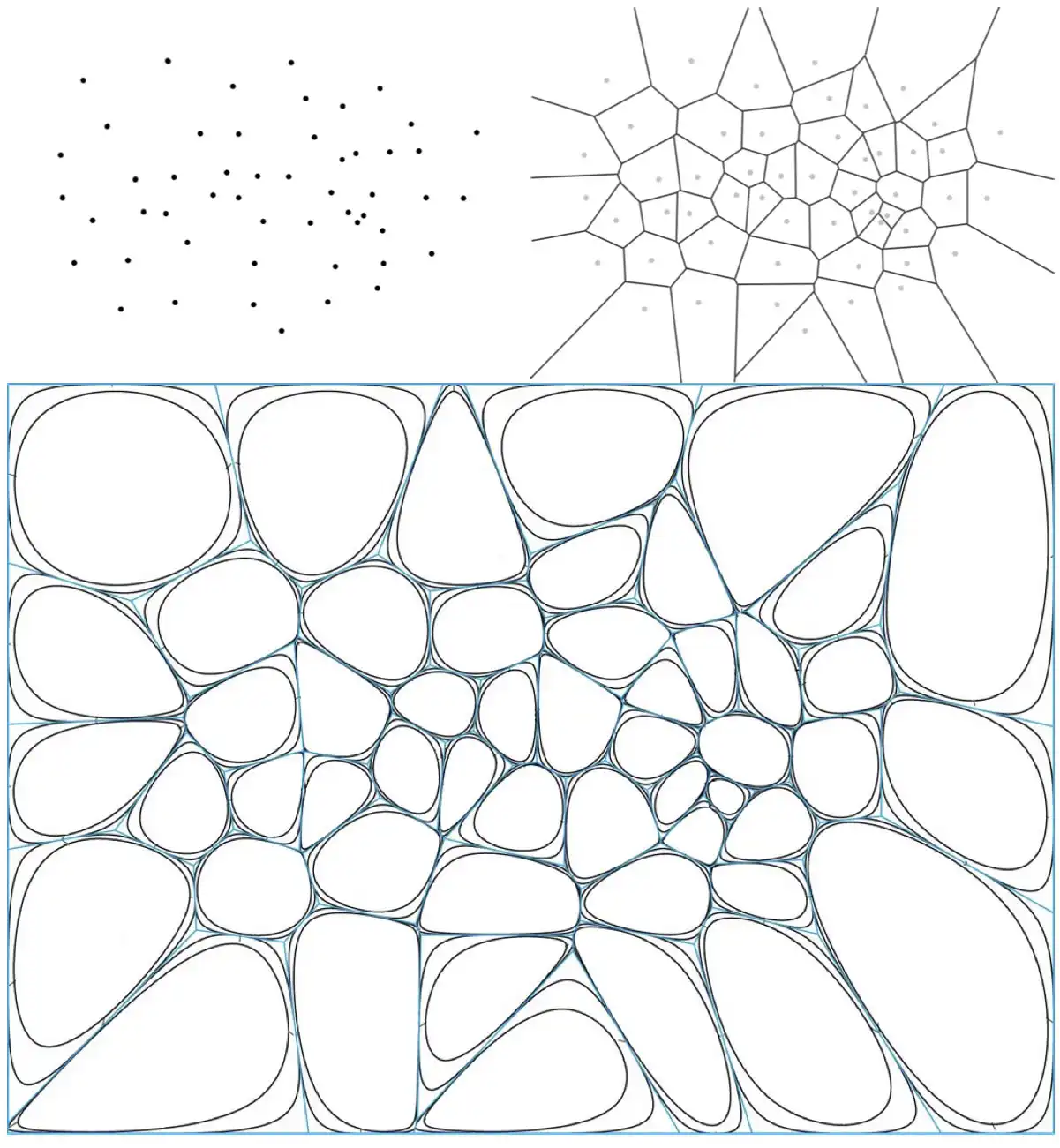

What’s most critical is that the Voronoi diagram is defined by mathematical rules. It’s like finding a magical bridge: one end connects to the 1,200 sets of human data we’ve collected, and the other leads to the naturally optimal structure. Through calculation, we can map each individual’s data directly into a unique, perfect support structure.

The Prototype Takes Shape

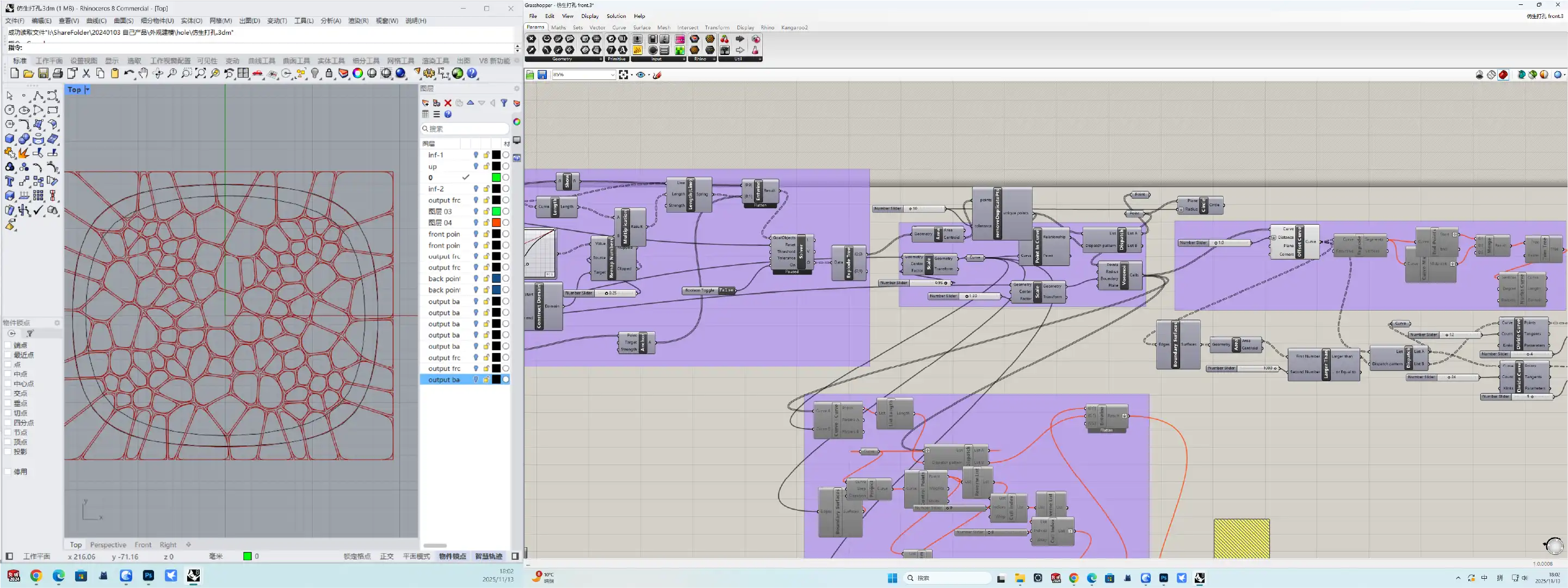

With the key inspiration of the Voronoi diagram, our next step was to transform it into a practical design. We adopted a parametric modeling approach and went through multiple iterations. It’s a high-precision but extremely detailed process. After thousands of calculations and simulations, we finally found the optimal balance in the software.

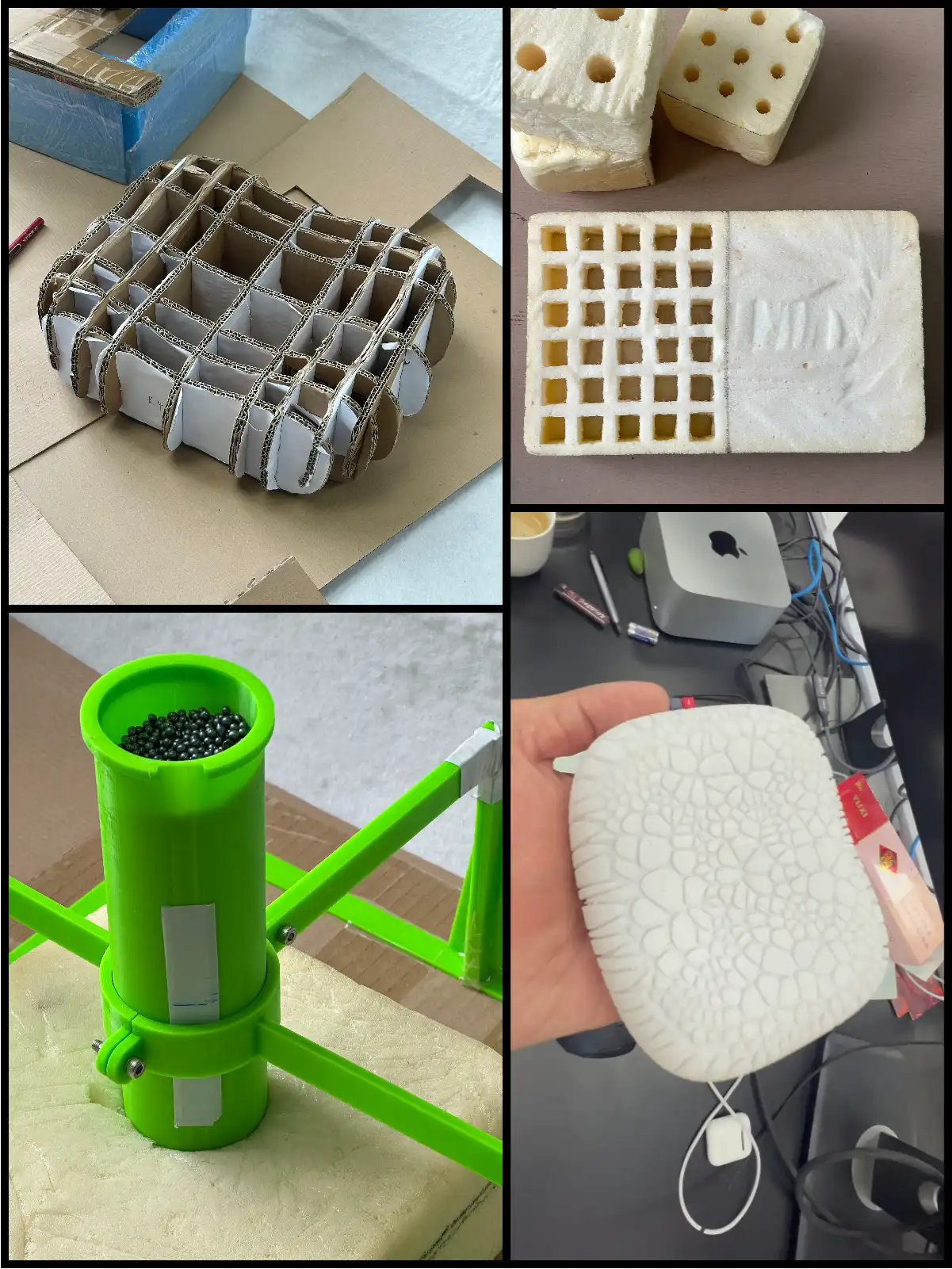

Next came the transition from digital models to physical validation. We personally conducted foam experiments to test the support, breathability, and rebound properties. At the same time, we created scaled cardboard models to precisely verify the height differences and curvature. Through this repeated iteration, the first functional prototype was born.

Searching for Manufacturing Partners

The unique design brought manufacturing challenges. RestBase features complex curves and zoned sections. What we needed was a partner who not only understood our design vision but also had the precision manufacturing capabilities to bring it to life.

So, we embarked on the journey to find the right factory. Most factories expressed strong interest but stated it was beyond their capabilities. This search reached an impasse for a while, but we never gave up.

Securing the Partnership: After numerous rejections, we finally caught a break. A well-established factory with extensive experience demonstrated a deep understanding and alignment with the RestBase design concept.

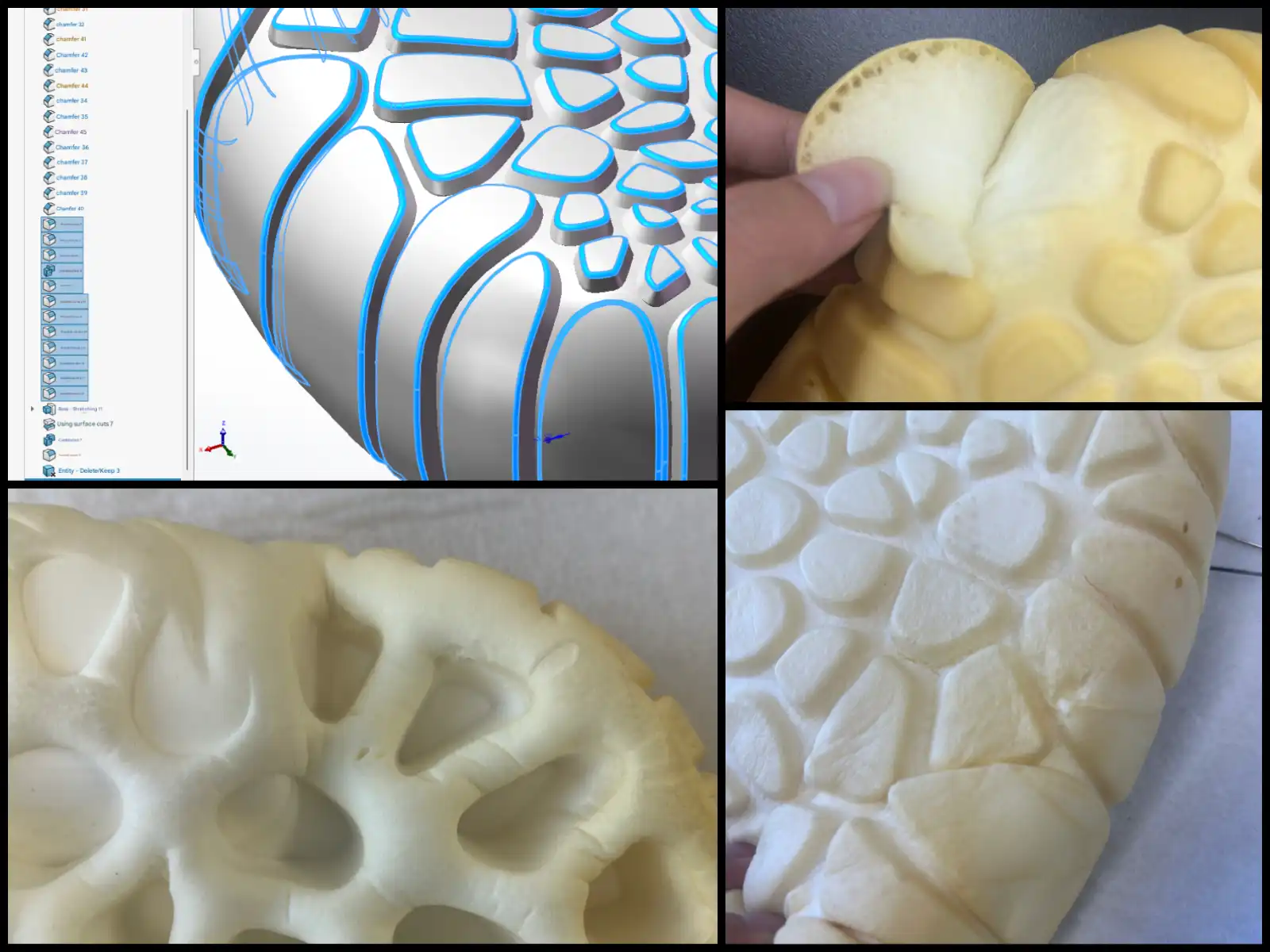

From Design to Mold: Turning the design into a manufacturable mold marked the beginning of a new challenge. The first issue was the overly fine zoning, which caused foam defects. We had to recalibrate the zoning dimensions. Then came the challenge of mold release. After months of repeated adjustments, the high-precision metal molds were finally completed.

Refining the Details

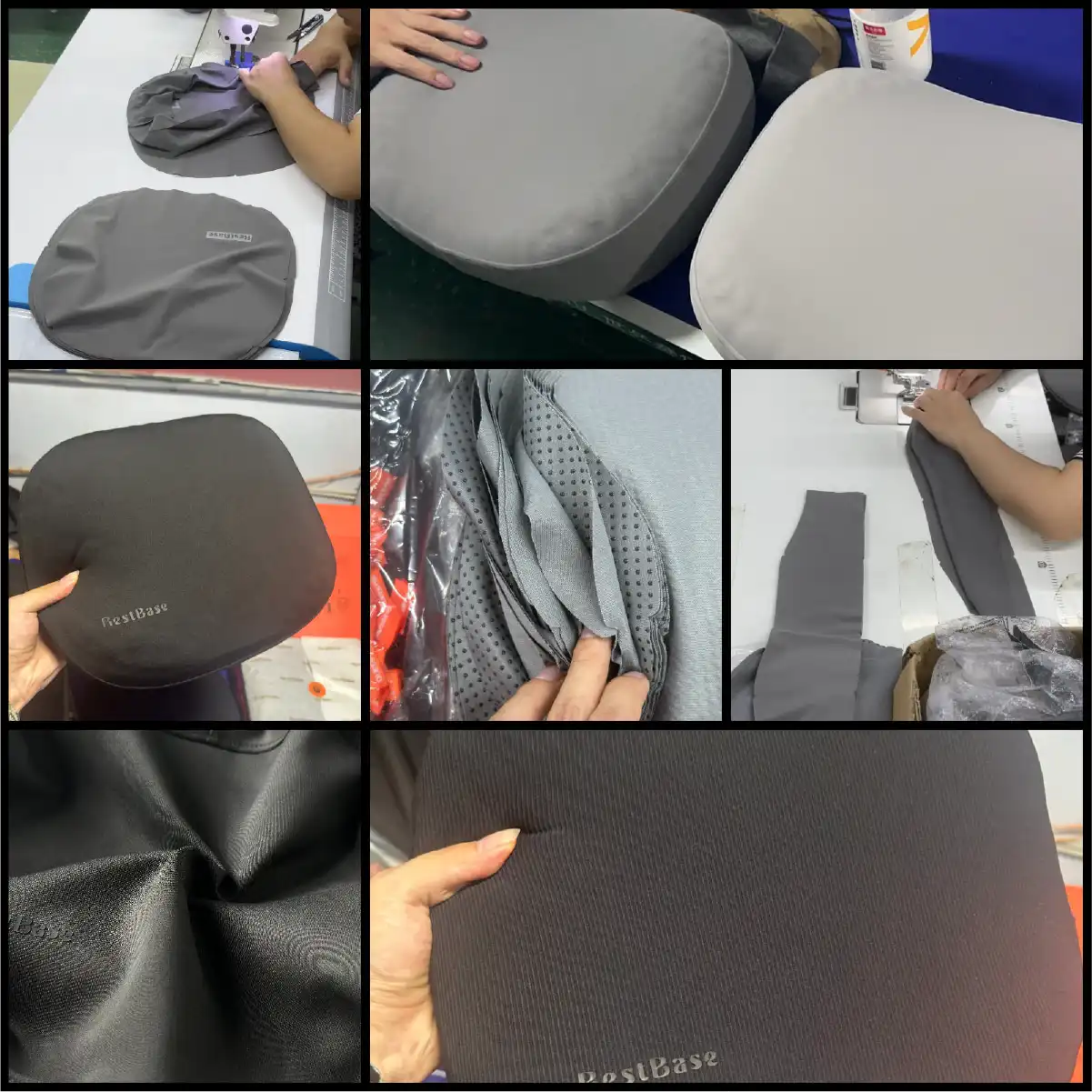

After completing the mold, we shifted our focus to perfecting the details. The first challenge was the pillow core's firmness. Through extensive sampling and testing, we continuously adjusted the ratio of memory foam, ultimately finding the perfect balance.

The pillowcase design also went through several iterations. In the end, we chose a thicker, highly elastic, and skin-friendly sports fabric, which provided a more durable, comfortable, and premium feel.

A Better RestBase Beta

After countless rounds of adjustments, trials, and optimizations, we are proud to present RestBase Beta—the result of dedicated effort from the SXDesign team and all of our partners.

At last, we can confidently showcase this creation and look forward to it becoming a part of your daily life.

Project Timeline

July 2024 - Idea Conception

August 2024 - Official Project Kick-off

September 2024 - Market Research, Sketches & Brainstorming

October 2024 - Simulation Experiments & Foam Testing

February 2025 - Design Finalization & Prototyping

March 2025 - Factory Visits & Partner Selection

May 2025 - Version 1.0 Realized

June 2025 - Small-batch Beta Testing & Feedback

July 2025 - Design Optimization based on Feedback

October 2025 - Final Version 2.0 Locked